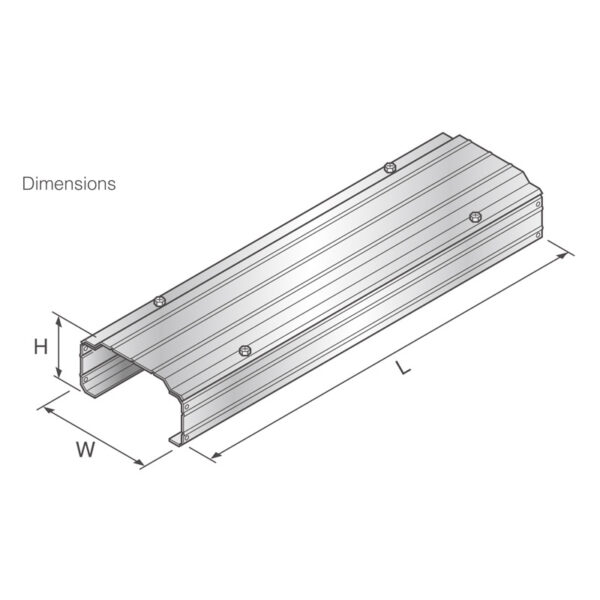

The Slimduct RD Commercial Lineset Cover offers a sleek, cost-effective solution for protecting and concealing multiple linesets in VRF/VRV systems. Designed for flexibility, it installs easily and adapts to any layout or orientation. A smart alternative to custom ducting, Slimduct RD saves labor while delivering a clean, professional finish.

Its durable, scratch-resistant coating—made from zinc, aluminum, and magnesium—is anti-corrosive and chromium-free, offering superior protection compared to traditional galvanized steel. Slimduct RD also includes the RDW line, featuring an embossed anti-slip surface that allows maintenance personnel to walk on it safely for easier access and service.