The Slimduct REC End Cap is designed to neatly close off the end of RD ducts where the lineset terminates, providing a secure and polished finish. As part of the Slimduct RD system, it offers durable protection for commercial VRF/VRV installations while enhancing the overall appearance of exposed linesets. Ideal for completing any installation with a clean, professional look.

REC End Cap

The Slimduct REC End Cap covers the duct end where the lineset finishes, providing secure closure and a clean, professional look for commercial installations.

- Attractive: Slimduct RD encloses the multiple lines used by variable refrigerant flow/volume (VRF/VRV) multi-split systems. Requiring less pace than traditional racking/jacketing system, its compact design delivers a clean, professional and finished look to any rooftop project. It blends in perfectly with any type of commercial building.

- Multiple Applications: A wide array of fittings, including risers, vertical mountings, and under-slab mountings, are readily available to easily customize while on the job site, during the installation process. Slimduct RD can also be installed in any orientation.

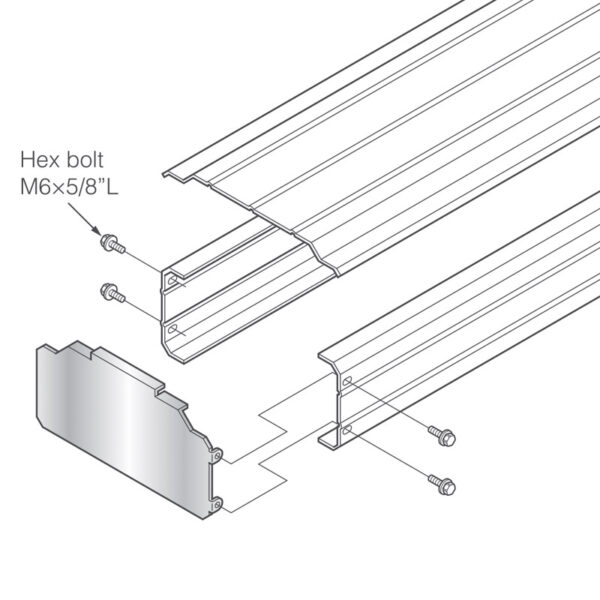

- Easy to Assemble: Slimduct RD is engineered to make installation a time-saving process. No special tools are required to assemble and connect the interlocking covers together. The screws needed, are included with the product.

- Durability: Fabricated from sheets of high-grade, corrosion-resistant and hot-dipped, galvanized steel, Slimduct RD is coated with zinc, aluminum, and magnesium. This scratch, abrasion and corrosive resistant coating offers better protection than stainless steel, even in highly corrosive environments such as coastal areas.

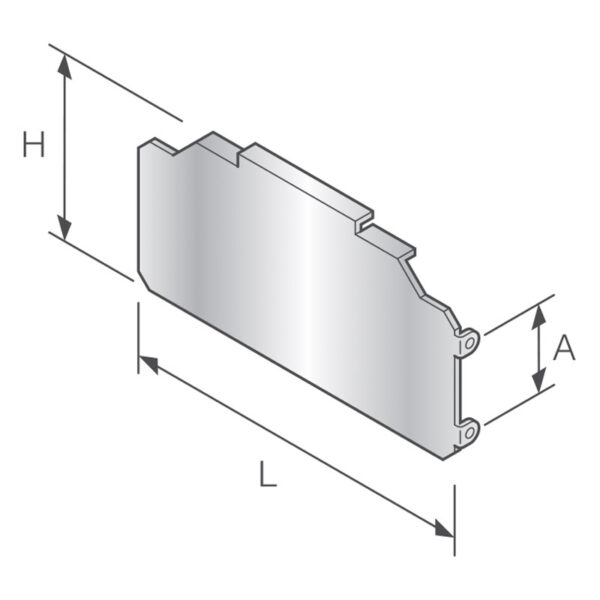

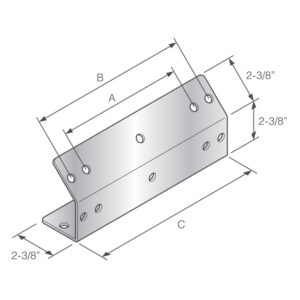

| Code No. | Item No. | L | H | A | Pcs/Pkg |

|---|---|---|---|---|---|

| C 77215 | REC-150-ZA | 6″ | 4-3/8″ | 2-3/8″ | 1 |

| C 85975 | REC-300-ZA | 11-3/4″ | 5″ | 2-3/8″ | 1 |

| C 85985 | REC-450-ZA | 17-5/8″ | 5″ | 2-3/8″ | 1 |

| C 85995 | REC-600-ZA | 23-1/2″ | 5″ | 2-3/8″ | 1 |

| C 88335* | REC-900-ZA* | 35-3/8″ | 5″ | 2-3/8″ | 1 |

| C 84645 | REC-300H-ZA | 11-3/4″ | 9-3/4″ | 5-3/8″ | 1 |

| C 86005 | REC-450H-ZA | 17-5/8″ | 9-3/4″ | 5-3/8″ | 1 |

| C 86015 | REC-600H-ZA | 23-1/2″ | 9-3/4″ | 5-3/8″ | 1 |

| C 88315* | REC-900H-ZA* | 35-3/8″ | 9-3/4″ | 5-3/8″ | 1 |

| * Special Order Only | |||||

| Material: Highly corrosion-resistant hot-dip galvanized steel shet has a coating layer of zinc, 6% aluminum and 3% magnesium. | |||||

Q. Can this be used in soil affected by salinity?

A .Yes. Please refer to the Instruction Manual for details.

Q. Can the standard type withstand a person’s weight? Can it act as a passage?

A . The standard type is not designed to be load-bearing. There is a walkway type designed to bear the weight of an average person. However, it is only meant to be used as a temporary path for maintenance purposes and not as a normal walkway.

Q.The surface is starting to rust. Is it not resistant to corrosion?

A . It is corrosion resistant but not corrosion proof. Scratched on the surface made during the installation a nd regular use may cause rust to appear prematurely. Additionally, over many years, the layers of zinc protective coating will degrade and rust may appear. Please refer to the Product Catalog or Instruction Manual for details.

Q. I want to switch from the standard type to the walkway type. Can I just change out the cover? A . No. The supports will have to be upgraded to the heavier-duty types to support the additional weight.

Q.What kind of brackets should I use to mount it on the wall?

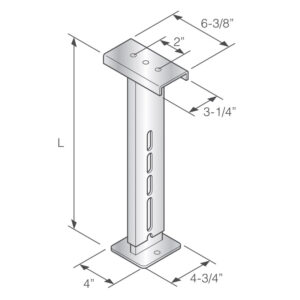

A . Please use the S Type RZM Bracket and RZB Riser. When doing the RD-150 type installation, please use the 300 S Type or other brackets (such as RZW) used for mounting to the wall. Please do not use a bracket that is longer than the S type because it will lose its center balance on the wall and problems resulting from the installation may arise. Please use an S Type or some other bracket meant for the wall.

Q. Is it possible to buy just a reinforcement plate?

A . Yes. Please contact Inaba Denko-America or your nearest dealer.

Q. Do I need a wall plate or wall sleeve?

A . Generally speaking, yes, it is necessary. A wall plate or wall sleeve is used to prevent and dispose of rainwater penetrating the building. You can do without a wall plate or wall sleeve by disposing of water in other ways such as creating a chamber box.

Q. If I install a standing Wall Sleeve or Wall Plate, will it completely stop the water?

A . If it is installed as per the Instruction Manual, the standing water can be prevented. However, there is no guarantee of that in all cases. The wall plate has been tested and confirmed that there were no signs of water penetration when installed properly.

Q. Can I use a free joint in place of a fixed joint?

A . If it sits level to the ground, yes. However, it is not recommended since the degree of strength after installation declines over time. For better fitting, refrain from continuous use of free joint and corner connections.

Q. What should I know when cutting a straight line duct?

A . Please use a high-speed cutter (nippers, snips, cutting wheel, etc.). If it is larger than the 450 type, we recommend using a cutting wheel. To prevent the cut surface from corroding, make sure after using a file to deburr the cut edge, apply an anti-rust treatment (a Zn-Al type or zinc-rich paint).

You May Also Be Interested In

RSP Cut Wall Plate

The Slimduct RSP Wall Plate features a built-in recess for sealant, making caulking easier and...

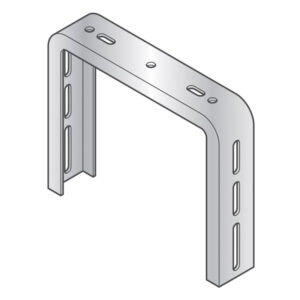

RZC Bracket Attachment Plate for Vertical Ell

The Slimduct RD Bracket Attachment Plate for Vertical Ell elevates the duct over wall or...

RZ 150 Single Bracket

The Slimduct RZ-150 Bracket elevates horizontal RD installations for obstacle clearance and secure support, ensuring...

RZM Bracket

The Slimduct RZB Riser and RZM Bracket elevate RD ducts over wall obstacles, ensuring smooth...