Vertical lineset installations often face significant stress from thermal expansion and gravity, leading to deformation and buckling—especially at the lower ends of pipe runs. The LineBrace Base Bracket is engineered to eliminate these issues by providing a central fixed point that acts as a fulcrum. This directs thermal movement both upward and downward while supporting the full weight of the lineset. Designed to simplify installation and improve system stability, LineBrace is the smart, reliable solution for secure vertical pipe support.

SKU

TKL-B60

Categories Pipe Support, Vertical

Tags Commercial Pipe Support, Pipe Support, Vertical Pipe Support

Brand: LineBrace

SKU

TKL-B60

Categories Pipe Support, Vertical

Tags Commercial Pipe Support, Pipe Support, Vertical Pipe Support

Brand: LineBrace

TKL-B Base Bracket

Prevents buckling in vertical linesets. Central fixed point supports weight and controls thermal movement. Easy to install.

- Reduced weight

- Reduced thermal expansion

- Easy to install pipe support

- Compatible with most pipes

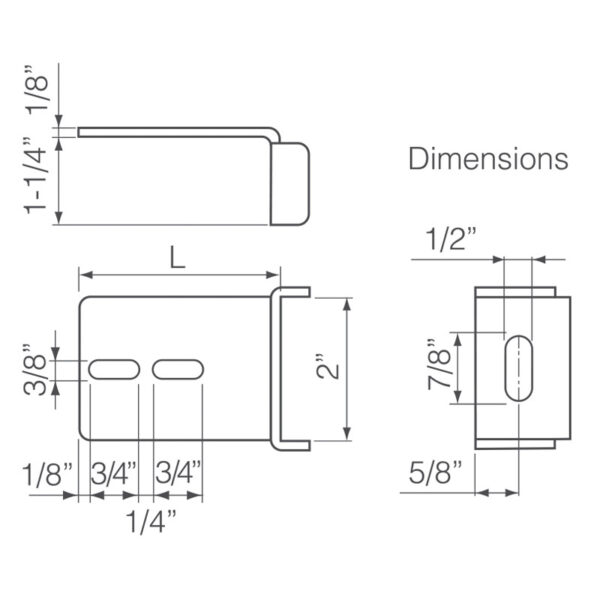

| Code No. | Item No. | L | Pcs/Pkg |

|---|---|---|---|

| C 51820 | TKL-B60 | 2-5/8″ | 100 |

| C 51821 | TKL-B70 | 3 | 100 |

Material: Hot dip galvanized and powder coated steel

Q. What benefit does LineBrace have over other traditional cushion-type clamping methods?

LineBrace was designed to carry the weight of a copper lineset riser and is to be used in conjunction with cushion-type clamps and not as a replacement. The LineBrace is meant to be installed in the center of the riser with cushion-type clamps being used above and below. This application also splits the thermal expansion 50% above and below the LineBrace.

While cushion-type clamps hold the piping in place, they are not designed to carry the weight. The synthetic bushing eventually degrades and the lineset drops, causing kinks or other piping damage that can limit a system’s capacity or cause catastrophic compressor failure.

There is no other product on the market like it today.

Q. With metal-on-metal clamping; does the LineBrace have dissimilar metals corrosion issues?

A. Not at all. The LINEBRACE assembly consists of a type 304 Stainless steel clamp, which is attached directly onto the copper piping of an air conditioning lineset riser. Both Stainless steel and copper compatibilities may be found in a noble metals chart. The level of nobility between copper and stainless steel is small therefore electrolytic corrosion is not considered an issue when using LINEBRACE.

Additionally, the Base Brackets are made of hot dipped galvanized and powder coated steel to protect against corrosion. The Temporary Clamping Plate included in the assembly, also serves as dielectric protection between the stainless-steel clamp and the base bracket.”

You May Also Be Interested In

TKL LineBrace Vertical Lineset Support

LineBrace supports vertical lineset risers in VRF/VRV systems and reduces thermal expansion stress on the...

TKL-K Base Bracket (Wall Mounting)

Enables secure wall mounting of the LineBrace Clamp for vertical lineset support. Provides stable anchoring...

TKL-U Base Bracket (Top-Mounting)

Securely anchors the LineBrace Clamp at the top of vertical lineset runs. Provides stable, load-bearing...

TKL-H Insulation

Protective insulation for vertical linesets. Resists compression and works with LineBrace to prevent damage from...